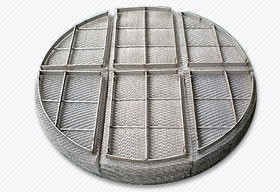

MONEL® alloy 400 (UNS N04400) Mist eliminator

A Nickel-Copper alloy mist elimiantor demister , resistant to sea water and steam at high temperatures as well as to salt and caustic solutions.

Alloy 400 mist elimiantor demister is a nickel-copper alloy with excellent corrosion resistance in a wide variety of media. The alloy is characterized by good general corrosion resistance, good weldability and moderate to high strength. The alloy has been used in a variety of applications. It has excellent resistance to rapidly flowing brackish water or seawater. It is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. The alloy is slightly magnetic at room temperature. The alloy is widely used in the chemical, oil and marine industries.

Characteristics

- Corrosion resistance in an extensive range of marine and chemical environments. From pure water to nonoxidizing mineral acids, salts and alkalis.

- This alloy is more resistant to nickel under reducing conditions and more resistant than copper under oxidizing conditions, it does show however better resistance to reducing media than oxidizing.

- Good mechanical properties from subzero temperatures up to about 480C.

- Good resistance to sulfuric and hydrofluoric acids. Aeration however will result in increased corrosion rates. May be used to handle hydrochloric acid, but the presence of oxidizing salts will greatly accelerate corrosive attack.

- Resistance to neutral, alkaline and acid salts is shown, but poor resistance is found with oxidizing acid salts such as ferric chloride.

- Excellent resistance to chloride ion stress corrosion cracking.

Applications for mist elimiantor demister.

- Feed water and steam generator tubing.

- Brine heaters, sea water scrubbers in tanker inert gas systems.

- Sulfuric acid and hydrofluoric acid alkylation plants.

- Pickling bat heating coils.

- Heat exchangers in a variety of industries.

- Transfer piping from oil refinery crude columns.

- Plant for the refining of uranium and isotope separation in the production of nuclear fuel.

- Pumps and valves used in the manufacture of perchlorethylene, chlorinated plastics.

- Monoethanolamine (MEA) reboiling tube.

- Cladding for the upper areas of oil refinery crude columns.

- Propeller and pump shafts.

Available specifications:

Diameter:1000-4100mm

Thinkness:100-200mm

Filtration rating: 98%-98.9%

Chemical Composition, %

| Alloy |

Ni |

Cu |

C |

Mn |

S |

Si |

Fe |

| Monel 400 |

63.0min |

28.0-34.0 |

0.30max |

2.00 max |

0.024max |

0.50 max |

2.50 max

|

Tensile Data

Mechanical Property Requirements

|

|

|

Ultimate Tensile

|

Yield Strength (0.2% OS)

|

Elong. in 2 in. or 50mm (or 4D), min.,%

|

R/A

|

Hardness

|

|

Cold Worked/SR

|

|

Min

|

87 KSi

|

60 KSi

|

20B

|

|

|

|

Max

|

|

|

|

|

|

|

Min

|

600 MPa

|

415 MPa

|

|

|

|

|

Max

|

|

|

|

|

|

|

Hot Worked/SR

|

|

Min

|

80 KSi

|

40 KSi

|

30D

|

|

|

|

Max

|

|

|

|

|

|

|

Min

|

552 MPa

|

276 MPa

|

|

|

|

|

Max

|

|

|

|

|

|

B- not applicable to diameters or cross sections under 3/32 in (2.4mm).

D-For hot-worked flats 5/16 in. (7.9mm) and under in thickness the elongation shall be 20% min.

Specifications

|

Form

|

Standard

|

|

Metal Type

|

UNS N04400

|

|

Bar

|

ASTM B164 QQ-N-281 Din 17750

|

|

Wire

|

|

|

Sheet

|

ASTM B127 QQ-N-281

|

|

Plate

|

ASTM B127 QQ-N-281

|

|

Pipe

|

ASTM B165

|

|

Tube

|

ASTM B165

|

|

Fitting

|

|

|

Forging

|

ASTM B564

|

|

Weld Wire

|

FM 60/ ERNiCu-7/ 17753

|

|

Weld Electrode

|

FM 190 ENiCu-7

|

|

Din

|

2.4360

|

|